Hands Behind the Dial – 10to2 Sits Down With Simon Michlmayr

Located in the heart of Norfolk, it’s easy to overlook one of Britain’s hidden treasures in horology and business: Michlmayr & Co.

Michlmayr’s is a second-generation watch and clock company situated in a discreet location just north of Norwich. It houses an intricate workshop, TAG Heuer and Omega approved service centre, and more watch parts than any single collection could use in 50 lifetimes. Nestled in a lab-like, access-controlled room is an array of mechanical machinery used to craft exquisite timepieces, designed and constructed by Simon Michlmayr and his team.

10to2 sat down with Simon Michlmayr to delve into the history of Michlmayr’s and to hear how a passion for horology has driven decades of innovation, adventure and excellence as one of the very few independent watch makers left in the UK. We are talking the upper echelons like that of Roger Smith in craft, capability and potential.

“Look at this, a circa 1940’s LACO which was used by a local sailing club to time races. Someone mentioned they thought it required a service when the reality was – a full overhaul was needed”

It didn’t take long for Simon’s passion and enthusiasm to flood out. On the bench was a 60mm (you read that right, a wrist-sized wall clock) LACO Pilots watch from the 2nd World War.

“This was brought over from the US and the sailing club has had it for over 30 years. With the watch being of German heritage, I can only assume that a G.I decided to keep it as a souvenir and took it back home when the war was over”.

Opening the caseback, Simon showed us the level of craftmanship LACO went to. “There is no anti-shock protection, over the years any small bumps or knocks would have seriously impacted the performance of this watch”.

We had to grab a photo, as the large case, which was designed to sprawl over the top of a flight suit was encompassed with meticulously well finished gold parts. We were in for a treat.

A family passion

Well-travelled readers may assume that Michlmayr is a rather unique surname. “My father was Austrian, having met my mother and moved to England to marry, they never moved back”.

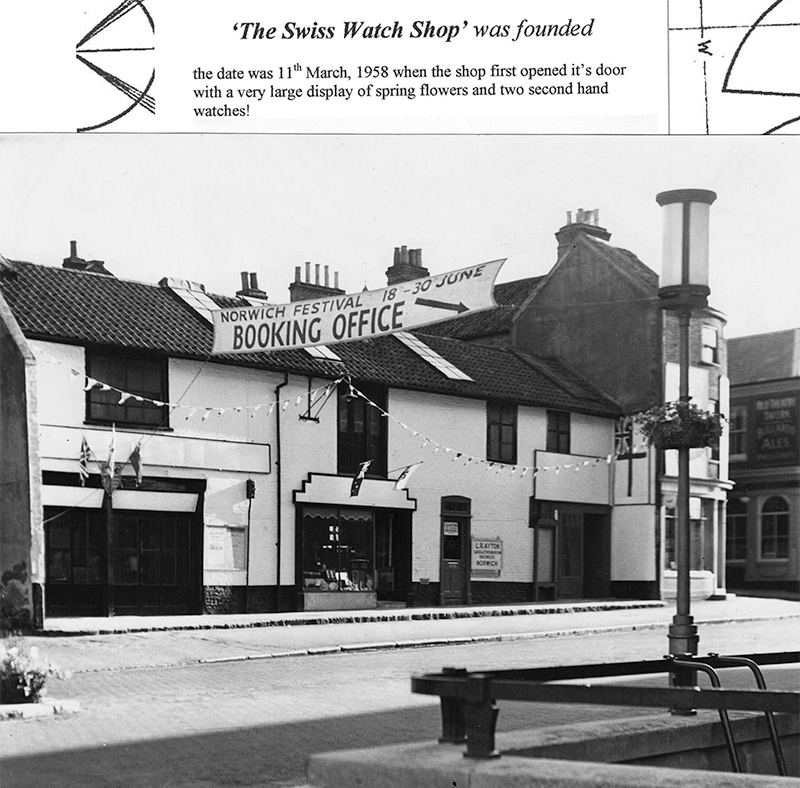

Simon’s father had a passion for mechanical objects, from traditional grandfather clocks to the early servicing of wristwatches. The original shopfront was a changing piece of history. “Situated in Norwich in the late 50s, it always seemed as if the council was out to get Dad. Wherever he moved, they followed – replacing the shop by first erecting a library, and who knows what else. We eventually settled in the historic, cobbled stoned street in the heart of the city. This was the start & formed the basis of a long-standing partnership with Omega and Tissot”.

Jumping seconds and pushing boundaries

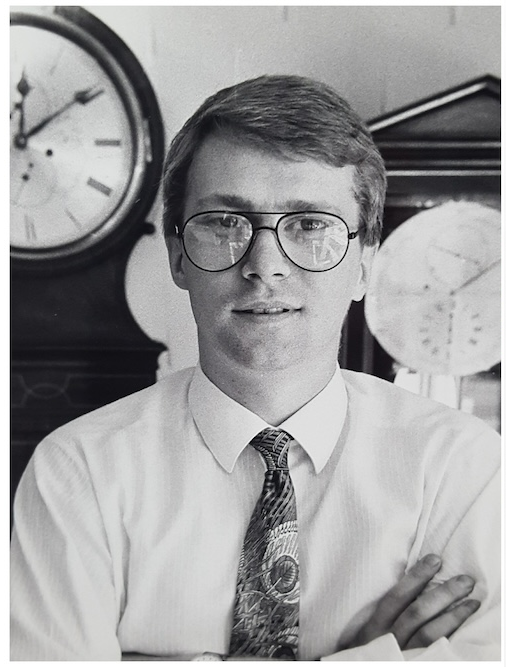

Simon was almost certainly destined to enter a horological career. Although he started off sweeping floors, he took a hawk-eyed approach to ensure what adorned his father’s workbench wasn’t too far away. Simon relished in the challenge of overcoming issues when working within metrics more akin to microns than millimetres.

Sporting a white-lab coat with an accompanied loupe (one eyed magnifying glass!), on Simon’s wrist was one of a kind – a watch with multiple personalities.

“I am wearing what you could call a prototype, a research & development watch that I cannot leave alone”. The watch in question is a descendent of an early Garrick model. Garrick is a watch brand owned and manufactured by Simon and his business partner, David Brailsford.

“We chose the name Garrick to reinforce the British heritage and for the avoidance of doubt, each Garrick is hand-made. This means that all watches are designed, manufactured and finished within our Norfolk HQ”

The exact model on Simon’s wrist was somewhat enigmatic, having undergone multiple iterations and being routinely used as a testbed for creating new movements, designs, and functionalities within a familiar case and style. “I am currently working on a jumping seconds hand movement, which is extremely unique within a mechanical watch.” Typically, unlike a quartz movement, mechanical (manual and automatic) watches have a second’s hand that ‘swoops’ across the dial, due to the way the gears release the power reserve stored in the mainspring. What Simon has achieved is the ‘tick-tock’ sensation synonymous with clocks – “It is very complicated – the jumping hand coupled with a power reserve display, makes this one of the first British watches to be made with this type of bespoke movement.”

Passion and precision

There is no doubt that Michlmayr’s is punching into the stratosphere of hand-made, pure mechanical luxury. Taking a moment with Simon to reflect on his journey over the last 40 years, to where he and the business has come from.

George: “Having the guidance and access to the watch industry from an early age, what solidified your decision to leap into a rather unique industry?”

Simon: “I have many passions in life, but they are synergistic from one to the next. As we have touched on, I love mechanical objects: watches, cars, you name it. If I can fettle, repair, create – I just can’t get enough”.

In the early days of his career, Simon left his father’s business to further learn the watch craft in Switzerland; where else would anyone want to go other than horological mecca?

“The course I was on was incredible, it was an open-access parts library, and no challenge thrown at me was too much. I relished in the opportunity and spent countless hours continuously improving on whatever the last object I designed, manufactured or refinished”. We asked what is the hardest part of being a watch manufacturer?

“Knowing when to stop and accepting that the next item will inherently always be better than the last. To your eyes it might look perfect, but I struggle with putting things down. I’ve started to accept that lesson, reflect on what I would do different and make sure I subsequently do”

We can see that this philosophy has paved the way for Simon and his team to achieve an even higher level of excellence. After a stint in Switzerland, necessity brought Simon back to England to assist his father in running the family business. Sadly, shortly after his return, Simon’s father passed away. However, the legacy was carried on, with the ‘Omega Service Centre East’ being rebranded simply as ‘Michlmayr’s.’

The watchmaker to the explorer

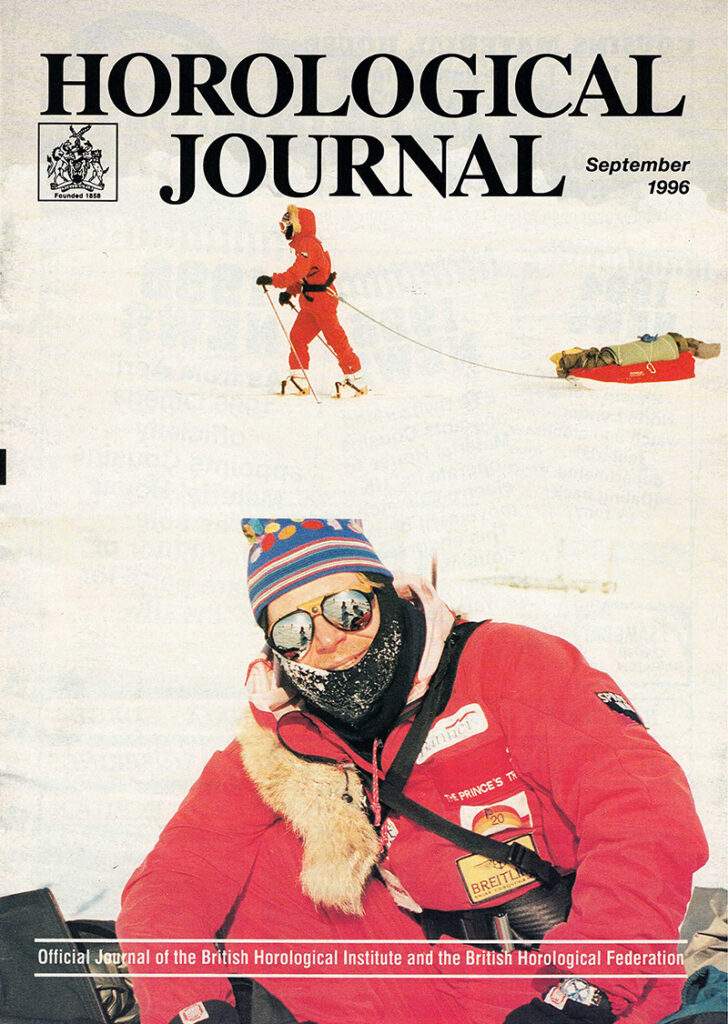

“Watches are one thing, but I also love adventure and the outdoors.” Simon’s face perked up and proceeded to tell us about a truly once in a lifetime opportunity. “I was fortunate enough to go on an expedition to the North Pole. It was led by now Sir David Hempleman-Adams, who was a Breitling ambassador at the time. I had to apply and go through a rigorous entry process which included undertaking the Sandhurst assault course, various psychometric testing and basic officer training”.

Whilst there was a connection to watches, it wasn’t the reason Simon was successful in being selected to join the trip. However, as soon as Hempleman-Adams and the team discovered he was a watchmaker, they couldn’t send him off into the snowy tundra without a Breitling. Simon was given the choice of what he could have: “I chose a Breitling Chrono Colt, although I had to be a little careful as the sheer freezing temperatures, coupled with stainless steel was a sure-fire recipe for catching frostbite”.

Not many others, if at all anyone wore a watch. The Chrono Cult stood up to the test in the extremes. The team successfully made the round trip to the pole and back, and this served as inspiration for what was to come. “The Breitling was good, but at times it was tough to read. I thought to myself – ‘I can make something more-purposeful and legible in all weather’. As soon as I returned home, I started working on a personal project – The Meridian”

Meridian is another brand curated under the ownership of Michlmayr’s, driven by a personal use case of simplicity meets useability. The watch was such a success that a small number of Meridian watches are still produced upon request by the team.

“I beat the crap out of my watches, it doesn’t matter if I am abseiling down clock towers or getting stuck into engines. I am a keen racer, I would never take a watch off to protect it, that’s part of the character. Some of my watches get so dented I can’t even wear them until they get a service. It feels a bit like a busman’s holiday though, so they always go to the back of the queue!”

From Colditz to the workbench

We began exploring the types of work Simon and the team undertake, having access to an enormous pool of different watches from a myriad of brands.

GW – “Do you have any memorable stories that customers have shared when requesting a service?

SM – “So many of the timepieces that come to us have some form of a backstory. One of the most memorable in all these years of Michlmayr’s was a customer who brought in a Rolex from the 1940’s. On the surface, this appeared rather innoxious, but quickly was I sat listening to the history of the watch.

This example carried a story so peculiar and unique that it’s almost unbelievable. “This Rolex was purchased by someone who was prisoned in Colditz. It highlights a few things which we can ponder about now. 1 – the Swiss used to sell to anyone… and I mean anyone! And 2 – they were also happy with deferred payment until the persons release”. Simon has seen the associated dog tags and prisoner of war diary which further corroborates the story. The watch came in for a service, and the demonstrable quality of early Rolex’s meant that it was a straightforward clean and retune, no new parts were required to get this example back to ticking away at its best.

The changing landscape of watchmaking

The changing of the industry has introduced material risk for all independent watch service centres, let alone manufacturers. There has been a shift towards new, non-mailable materials such as silicone hairsprings; these can’t be mended or reshaped as part of a service.

“The industry has become tighter in the supply of genuine parts, here at Michlmayr’s we can craft pretty much anything from the traditional, malleable and ductile alloys such as aluminium or steel, but when you get into newly formed materials it adds complexity and ultimately requires brand-specific knowledge”.

Simon’s private office is situated on the top floor of a mezzanine, overlooking a team undertaking works on a large clock that had been removed for regular servicing. It’s not just modern material science or changes in the way brands partner with independents that cause his business continued challenges.

“Recruiting, training and retention of skilled employees is a continued balance of success and struggle. Courses available in the UK are extremely limited when it comes to horology, and there are less than circa 20 watch makers coming out of the UK’s education system each year. Most of these students are sponsored by the big Swiss conglomerates, meaning they earn a full salary during the course and have a job to fall right into”.

We delved into why this might be, and we quicky identify the similarities from other industries that have a small pool of ‘grail’ opportunities. If you grow up admiring cars, we all know that red means Ferrari, or motorsport success might mean Porsche. If a young, budding watch maker has an opportunity to work with Rolex, AP or Patek, you can’t compete as a Lotus or Ford.

However, it is not all doom and gloom, as the heightened interest in watches since the onset of COVID has brought many positive impacts to the industry and Simon’s businesses.

SM – “Garrick has a forward order book that is sold out for at least the next 2 years, Michlmayr’s has a waiting list for those wanting to service their clocks, and the service centre is busting at the seams”.

It is fantastic to hear that opportunity is presented no matter which direction Simon and the team are peering into. It’s even more impressive that the team still accommodate requests to provide the highest levels of customer service.

Pushing boundaries – Simon’s vision for the future

GW – “What is your vision for the future of Michlmayr’s?”

SM – “With watch manufacturing, the sky is the limit. I have a few personal projects I would like to undertake alongside the day-to-day operations. Being into car racing, I am currently modifying a Valjoux movement into a bespoke case design for myself and friends to time our laps with. This racing chronograph must be accurate to a tenth of a second, and it needs to be highly legible – we all have GPS and timing screens but frankly none of us want to use them”

Simon doesn’t stop there, if creating a watch for his racing outings wasn’t enough. “I have always wanted to create a diver’s watch, but if I am going to do it, it needs to be some form of record holder. Perhaps a deep-diver record for a British watch brand” – Judging by the sheer volume of work, don’t hold your breath on when it will happen, but we are confident when it does, Simon and the team will smash it.

Simon’s advice for aspiring watchmakers

As we start to round off the discussion, we wanted to understand what advice Simon would give to anyone who wants to enter the industry.

SM: “Truthfully, you need to think long and hard before becoming a watch maker. Do you have a passion and an eye for detail, would you prefer handling watches from multiple brands and potentially a sales job would be better suited? Or is product design your passion?”. There is a certain niche when looking for suitable candidates to join the watch servicing or making industry, but Simon hopes to attract and support those willing to learn, with Michlmayr’s fostering a superb culture of success. “I want to teach people what I know, how I’ve learnt and how to avoid the pitfalls and mistakes made throughout my career”.

The path of independence was not necessarily a chosen one. Michlmayr’s rich history could have been very different. Simon could have been working at any of the big Swiss watch makers but chose to return to his roots and steer the family business to new heights and many directions. What is evident, is that Michlmayr’s has huge opportunity in all areas. The domestic market on watch & clock repairs alone is enormous, and the tower clock maintenance skillset is as rare as hens’ teeth. The art and craft of watch manufacturing fuels the passion for continued success. Whether that is to satisfy middle eastern markets or create bespoke hand-turned engine dials in a variety of unique colours, we can’t wait to see the next chapter of Michlmayr and Simon, the man behind the dials.